Finding the Best Rice Milling Machine in India: A Comprehensive Guide

India, as one of the world’s largest producers and consumers of rice, boasts a vibrant and competitive rice milling industry. For entrepreneurs looking to enter this sector or existing millers aiming to upgrade, investing in the Best Rice Milling Machine In India is a critical decision. However, “best” is a highly subjective term, influenced by a multitude of factors unique to each business.

At Ricetec Machinery, we understand that the ideal machine is one that perfectly aligns with your specific operational needs, budget, and long-term goals. This guide will help you navigate the Indian market to identify what constitutes the “best” rice milling machine for your enterprise.

What Defines the Best Rice Milling Machine?

The definition of “best” isn’t about the most expensive or the largest machine. Instead, it’s a holistic assessment based on several key performance indicators and business considerations:

1. Capacity and Scalability: Matching Your Production Needs

- Small Scale (Mini Mills): Typically processing 100 kg/hour to 1 ton/hour. Ideal for individual farmers, small communities, or as a supplementary income source. Prices for these often range from ₹20,000 to ₹5,00,000 for standalone units.

- Medium Scale (Commercial Mills): Ranging from 2 to 5 tons/hour. Suited for businesses supplying regional markets, requiring a balance of automation and cost-effectiveness. A complete medium-scale plant might range from ₹25 lakhs to ₹50 lakhs.

- Large Scale (Industrial Mills): Processing 5 tons/hour and above. Designed for high-volume production, export-oriented businesses, and those aiming for significant market share. Fully automated large-scale plants can cost anywhere from ₹50 lakhs to over ₹5 crores, depending on features and technology.

The “best” capacity is one that matches your current paddy procurement and projected market demand, with room for future expansion. Overspending on excessive capacity or underspending on insufficient capacity can both lead to inefficiencies.

2. Level of Automation and Technology Integration: Efficiency vs. Investment

- Manual/Semi-Automatic: These machines require more manual labor for feeding, monitoring, and transfer between stages. They have lower initial costs but higher operational expenses (labor, potential for inconsistent output). They are often integrated units combining hulling and whitening.

- Fully Automatic: These plants feature automated feeding, sequential processing through various stages (cleaning, de-stoning, hulling, separation, whitening, polishing, grading, color sorting, packaging), and centralized control systems.

- Benefits: Higher efficiency, consistent product quality, reduced labor dependency, lower grain breakage, and better control over the milling process.

- Cost: Significantly higher upfront investment due to advanced machinery and control systems.

For businesses aiming for consistent, high-quality output and long-term profitability, a fully automated setup often proves to be the “best” long-term investment, despite the higher initial price.

3. Output Quality: Head Rice Yield and Appearance

A truly “best” rice milling machine excels at producing high-quality output, characterized by:

- High Head Rice Yield: Minimizing grain breakage during the hulling and whitening processes is crucial. More whole grains mean higher market value.

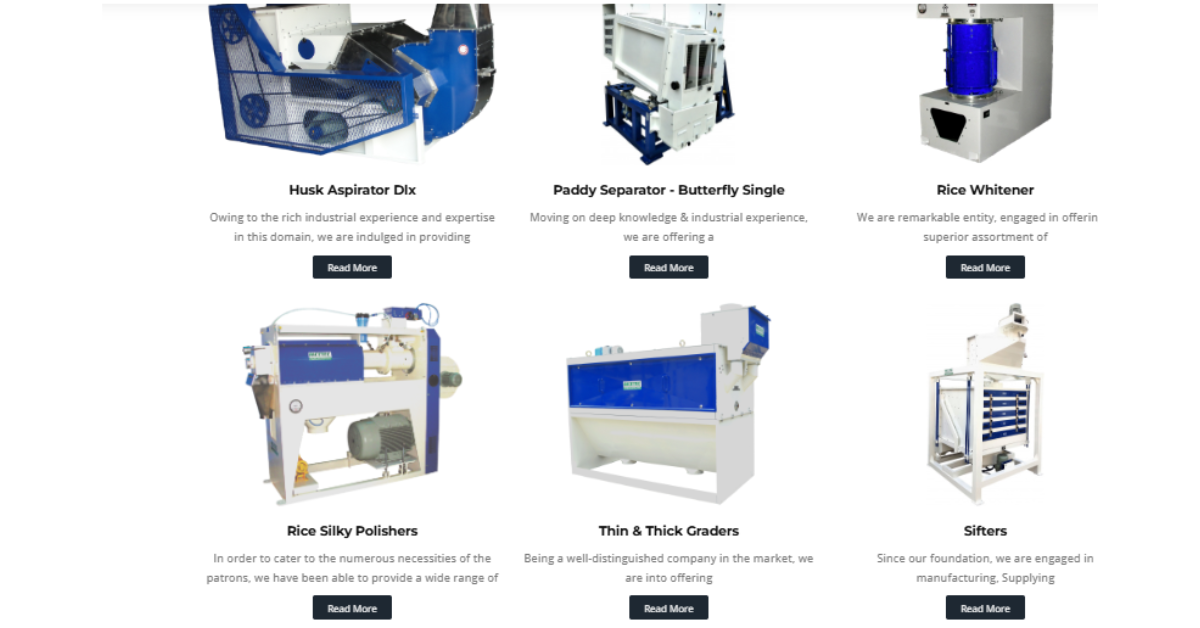

- Superior Whiteness and Polish: Multi-stage whitening and advanced Rice Polishing Machines (especially mist polishers or silky polishers) are essential for achieving the desired whiteness and a glossy, attractive finish.

- Purity: The ability to effectively remove impurities like stones, dust, discolored grains, and foreign matter. This is where high-performance Paddy Cleaners and precision Color Sorters become indispensable.

4. Durability and Build Quality: A Long-Term Asset

The “best” machines are built to last.

- Robust Materials: Use of high-grade steel, wear-resistant components, and durable parts for longevity.

- Precision Engineering: Well-engineered machines minimize vibrations, reduce wear and tear, and ensure consistent performance, leading to lower maintenance costs and fewer breakdowns.

- Ease of Maintenance: Simple designs for routine cleaning and accessible parts for repairs are vital for minimizing downtime.

5. Energy Efficiency: Operational Cost Savings

Electricity is a significant operating expense for rice mills. The “best” machines incorporate energy-efficient motors, optimized designs, and intelligent control systems to reduce power consumption, leading to substantial savings over the machine’s lifespan.

6. Comprehensive After-Sales Support and Spare Parts Availability

This is often the most overlooked yet critical factor. Even the most advanced machine can become a liability if it breaks down and spare parts or technical assistance are unavailable. The “best” manufacturers in India provide:

- Prompt Technical Support: Quick response to queries and issues.

- Ready Availability of Genuine Spares: Ensuring minimal downtime.

- Installation and Commissioning Services: Professional setup to ensure optimal performance.

- Operator Training: Equipping your team to run the machine efficiently and safely.

Leading Manufacturers of Rice Milling Machines in India

India is home to several reputable manufacturers known for producing high-quality rice milling machinery. While we are proud of our offerings at Ricetec Machinery, it’s important to be aware of the competitive landscape:

- Ricetec Machinery: Specializing in innovative and robust rice processing solutions, Ricetec offers a comprehensive range from paddy cleaners to complete automatic rice mill plants, focusing on efficiency, minimal breakage, and dedicated after-sales support. Our automatic rice mill plants can range from ₹35 lakhs to ₹45 lakhs for significant capacities.

- Sona Machinery: A well-known name offering end-to-end solutions, from pre-cleaners to color sorters and complete turnkey projects. They emphasize advanced technology and cater to various capacities. Their full automatic rice mill setups (4-12 TPH) are widely available.

- Suri Engineers: With decades of experience, Suri Engineers is recognized for quality and a wide range of machinery, including specialized units for cleaning, hulling, whitening, and polishing. They focus on delivering efficient and durable solutions.

- Annapurna Agronics Machinery Pvt. Ltd.: A prominent manufacturer known for their robust technology and manufacturing facilities, offering comprehensive rice mill machinery, including full plant setups. Their medium-scale plant setups can range from ₹25 lakhs to ₹50 lakhs, with larger plants exceeding ₹5 crores.

- Kinetic Group India: Known for advanced color sorters and increasingly comprehensive rice milling solutions, focusing on modern, efficient, and sustainable technologies.

- Bühler Group (Global Presence): A Swiss multinational with a strong presence in India, known for high-end, technologically advanced, and highly automated rice milling solutions, often catering to large-scale, export-oriented mills.

- Satake Corporation (Global Presence): A Japanese giant with a significant Indian footprint, renowned for its cutting-edge technology, particularly in optical sorting and precision milling.

How to Find the “Best” Rice Milling Machine for Your Business

-

Define Your Requirements Clearly:

- Capacity: How much paddy do you need to process per day/month/year?

- Budget: What is your realistic investment capacity for the machinery and associated infrastructure?

- Rice Quality Goals: What level of whiteness, polish, and purity do you aim for? (e.g., standard, silky, parboiled).

- Space Availability: Do you have enough space for the chosen machine or complete plant?

- Power Supply: Can your existing electrical infrastructure support the machine’s power requirements?

-

Conduct Thorough Research:

- Explore manufacturers’ websites (like Ricetec Machinery) to understand their product range and specifications.

- Read reviews and testimonials from other millers.

- Look for case studies of successful installations.

-

Request Detailed Quotations:

- Contact multiple manufacturers for quotes that include all necessary components (cleaner, de-stoner, huller, separator, whitener, polisher, grader, color sorter, elevators, control panel, etc.).

- Inquire about installation costs, training, warranty, and post-warranty service packages.

-

Evaluate After-Sales Support:

- This is non-negotiable. Ask potential suppliers about their service network, typical response times, and spare parts availability in your region.

- Try to connect with existing customers to get their direct feedback on after-sales service.

-

Consider a Site Visit:

- If possible, visit a working rice mill that has installed machinery from your shortlisted manufacturers. Observe the machines in operation, speak to the operators, and assess the overall efficiency and quality.

-

Seek Expert Consultation:

- A reputable manufacturer will be happy to offer expert advice, helping you select the most suitable machine based on your specific needs and current market trends. At Ricetec Machinery, we provide comprehensive consultations to guide your decision-making process.

Conclusion

The “best” rice milling machine in India isn’t a universal product; it’s the optimal solution tailored to your unique business model. By carefully considering factors like capacity, automation, output quality, durability, energy efficiency, and especially the crucial aspect of after-sales support, you can make an informed investment that will drive efficiency, productivity, and long-term profitability for your rice milling operation. At Ricetec Machinery, we are dedicated to partnering with you to find precisely that perfect solution.